Analyse stage

Analyse

Analyse the process

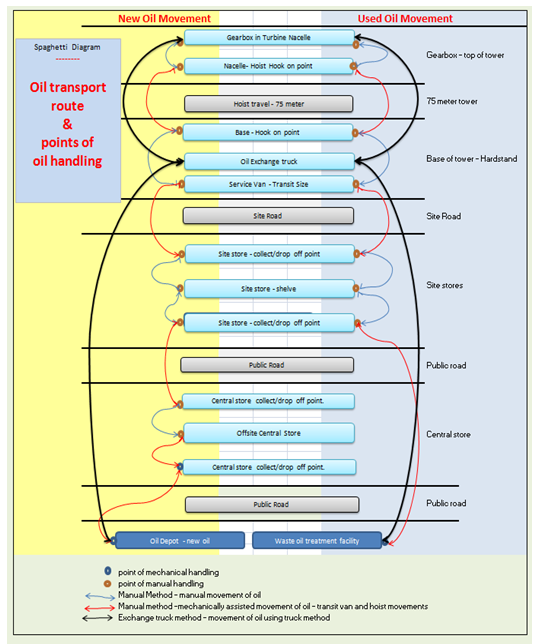

How does the process actually work -

Time value map for the oil change only. Time is mapped on

the assumption that the oil truck is parked at the base of the turbine ready to

go, and the service van is parked at the base of the turbine with an oil change

worth of 20 litre container and ready to go. VA is only added to tasks directly

changing oil at the gearbox. This excludes time/costs incurred for the

manual method with regards storage and transportation of the oil as far as the

base of the turbine.

We created a matrix to show the Value and Non Value Added tasks.

Using the time taken for the manual method as a baseline:

We generated a pie chart to compare VA and NVA time during the oil changes. We decided to used the greater time taken for the manual oil change as the reference time. This allowed the time saved in the truck oil change method to be presented as value added time.

Cost: Comparison and

cost : VA, Unavoidable NVA, Avoidable NVA and potential NVA

We broke the tasks into value and non-value added . We compared the costs in carrying out once off oil changes, which may need to be carried out in an unscheduled manner, possibly due to a breakdown. We also compared carrying out 3 oil changes in one day. 3 oil changes in one day would be representative of normal scheduled service oil changes.

Seven Wastes : Identify wastes

Taking the seven wastes and a few of the new wastes a comparison table was created.

Develop theories

and ideas

What does the existing process knowledge say -

5 Why’s – Oil truck Method

Why use the oil truck? Use the oil truck because it is

faster

Why is it faster? There is less manual handling involved

Why is there less manual handling involved? The truck pump and drains the oil directly at

the gearbox.

Why pump and drain the oil directly at the gearbox? It reduces opportunity for falling items and

manual handling incidents.

Why is reducing opportunity for falling items and manual

handling incidents an advantage? This

reduces the chances of personnel getting hit by falling objects, reduces the

chances of oil spills due to dropped containers and lost time due to manual

handling/back injury.

5 Why’s – Manual method

Why use the manual method? The truck is not available

Why is the truck not available? The oil change wasn’t scheduled

Why wasn’t the oil change scheduled? It was

a once off oil change due to a mechanical fault

Why not wait for an oil truck? The cost of the downtime outweighs waiting for the truck.

Why is the cost of downtime so important? The turbine generates an income when it’s

running. The performance of the wind turbine is measured by its annual running

time.

Analyse the data:

We created a matrix outline the costs, safety and environmental elements of the oil changes.

Conclusion for Analyse

Elements of analyse were painstaking, but the clear impact picture that was created of the elements of the oil changes will provide the valuable information required to drive the improvements.